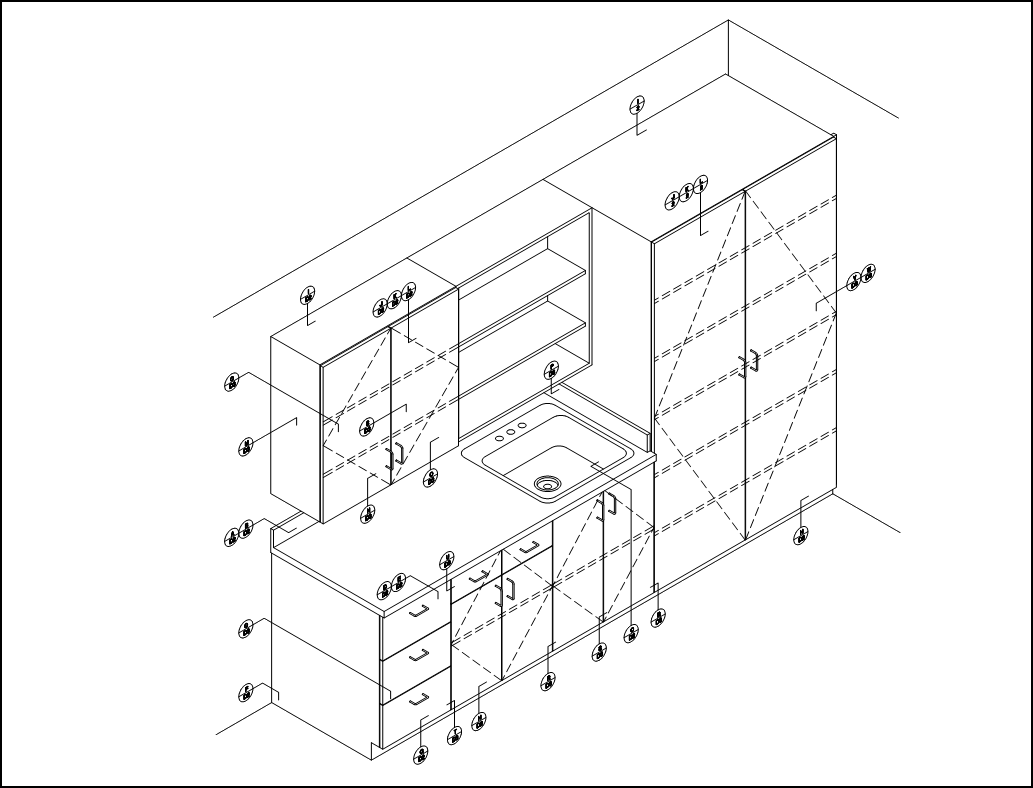

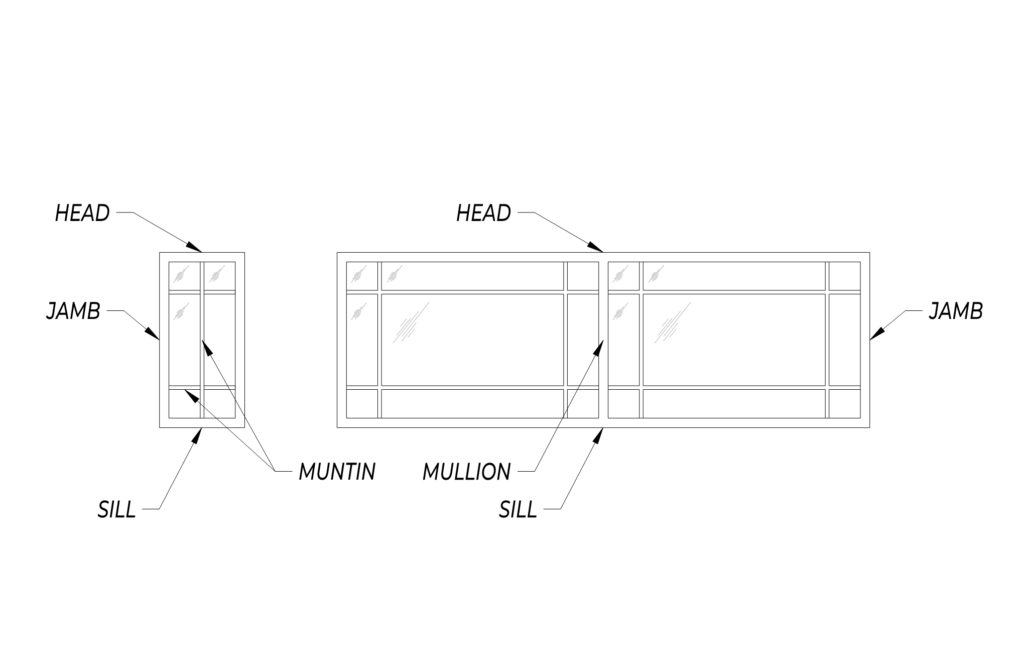

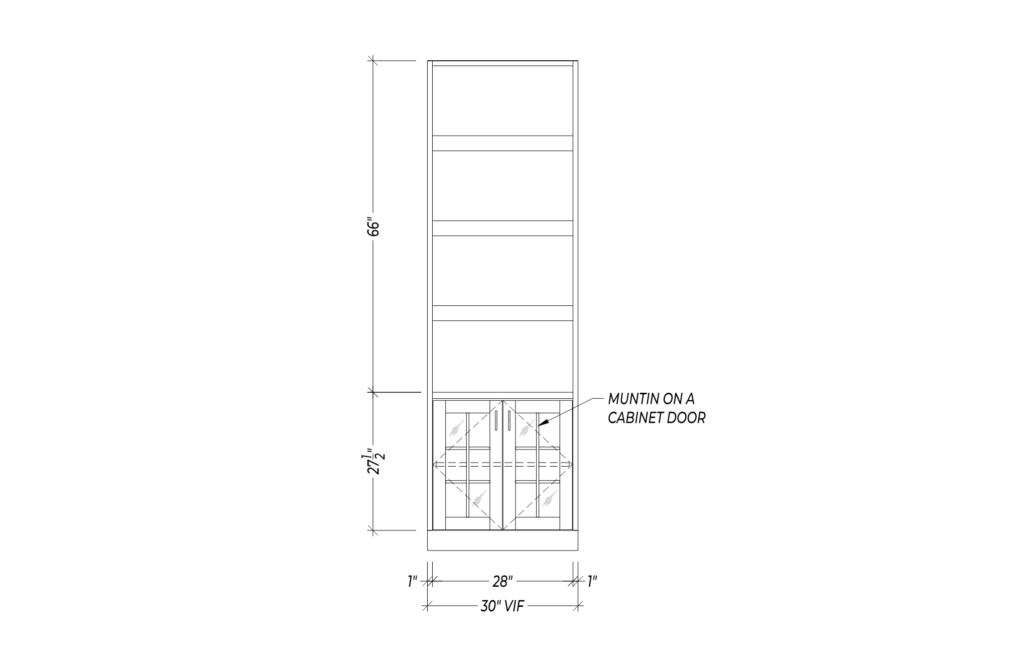

Casework and millwork shop drawings provide an invaluable resource for cabinet shop owners and engineering managers. These drawings are used to create precise details of the cabinets, shelves, drawers, doors, handles, hardware, etc., that will be included in a specific project. Professional casework and millwork shop drawings enable cabinet shops to accurately fabricate each piece of custom millwork or casework. Additionally, engineering managers can use casework and millwork shop drawings to plan out a project in advance, ensuring that it meets all of the necessary requirements.

Casework and millwork shop drawings are often used by cabinet shops to create mock-ups of their designs before they begin fabrication. This helps ensure that the finished product will meet the customer’s expectations and specifications. Casework and millwork shop drawings also provide accurate measurements of the finished product, which allows for a more precise installation process. Finally, casework and millwork shop drawings provide a visual representation of how the finished project will look once it is installed in its environment. This helps customers to visualize how their cabinets will look when they are finally completed.

The benefits of professional casework and millwork shop drawings extend beyond just cabinet shops and engineering managers. The detailed information that is provided on the drawings can be used by other trades and contractors to make sure their work is completed in a timely manner. Additionally, these drawings can be used for marketing purposes, as they provide an excellent resource to show potential customers examples of the quality of work that the company is capable of producing.

In conclusion, professional casework and millwork shop drawings are a valuable asset to both cabinet shop owners and engineering managers. These drawings can provide detailed information about each piece that will be included in a project, as well as an accurate representation of what the finished product will look like once it is installed. Additionally, these drawings can be used for marketing purposes, and they can help other trades and contractors to complete their work in a timely manner. By taking advantage of these benefits, cabinet shop owners and engineering managers can ensure that each project is executed with precision and accuracy.